Sterilization Impact Testing

Sterilization Modes

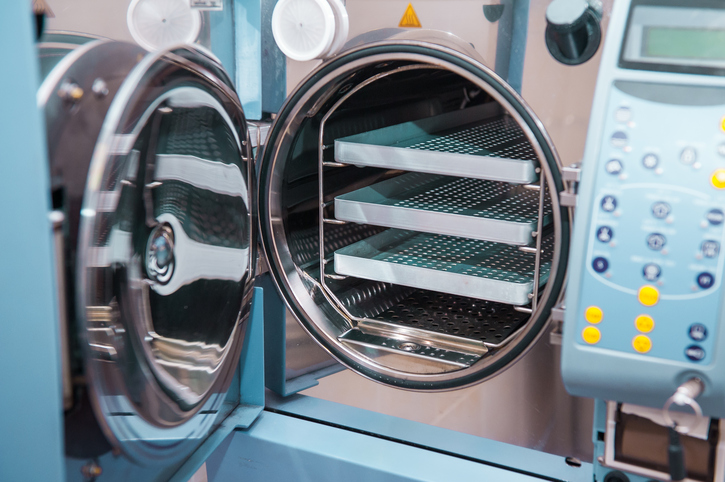

A variety of strategies are employed to sterilize medical devices and combination products to ensure they are free of viable microorganisms. Common sterilization modalities include:

- Gamma irradiation

- Electron beam (e-beam) irradiation

- X-Ray irradiation

- Autoclave

- Dry heat sterilization

- Ethylene oxide (ETO)

- Hydrogen peroxide

- Glass plasma

- Vaporized peracetic acid

Of course, no sterilization method can guarantee 100% elimination of microorganisms irrespective of the initial biological load or bioburden. Proper design and validation of upstream cleaning process is therefore a critical aspect of medical device development.

When developing a new medical device, or considering process changes to an existing device, a critical choice is the selection of the sterilization mode. When working with a device which may consist of multiple polymeric components, housings, seals, and connectors, such decisions should be made with care. CPG can assist your team in a careful review of the polymeric components and how they may each respond to sterilization. Such reviews are often best conducted early in the product development process, during initial material evaluation/screening and selection. Inclusion of additives such as gamma stabilizers may mitigate adverse effects of sterilization.

Sterilization Impact Characterization

CPG can also assist your team in characterizing sterilization impacts. Polymer products may see significant changes in their functional properties depending on the sterilization mode and conditions. Polymer chain scission, crosslinking, additive degradation, and resultant reactions can impact:

- Polymer Molecular Weight and Molecular Weight Distribution/Polydispersity

- Chemical Properties and Degradation

- Mechanical Properties

- Rheological Properties

- Surface Properties

- Swelling Characteristics, Water Content (Hydrogels)

However, it is critical to evaluate such material impacts in the context of the functional device requirements. Holistic, device-level testing may be employed to evaluate the overall device functionality and determine if sterilization has resulting in deviation from its acceptable operating bounds.

One particular area of growing interest is the impact of the sterilization on the chemical properties of the material. Sterilization may result in the formation of degradation products or reaction byproducts of either the polymer or its additive package. Such products may be evaluated as part of a risk assessment with regard to both the device efficacy and safety.

Finally, as new data comes to light during device development, a change from one sterilization modality to another may be necessary. CPG can assist with the experimental design and evaluation of potential alternative sterilization strategies to determine quantitative comparisons between modalities or sterilization parameters.

CPG is an ISO 9001 certified, 17025 accredited contract R&D and analytical testing lab. Contact us to see how we can work with you.