Quantifying Rapid Rheological Changes

Blood vessel with hemostatic agent

In the world of material science and product design, understanding and measuring rapid rheological transitions is crucial. These transitions, which can be triggered by various stimuli such as UV light, electrical fields, or chemical interactions, play a significant role in applications ranging from hemostatic agents to 3D printing materials. While standard methods exist for common applications, less conventional scenarios often lack specialized tools for accurate measurement.

The Challenge of Rapid Rheology Transitions

Conventional methods for measuring rapid rheological changes often face limitations:

- Large sample volume requirements

- Inability to capture transitions faster than one second

- Lack of quantitative accuracy for rapid changes

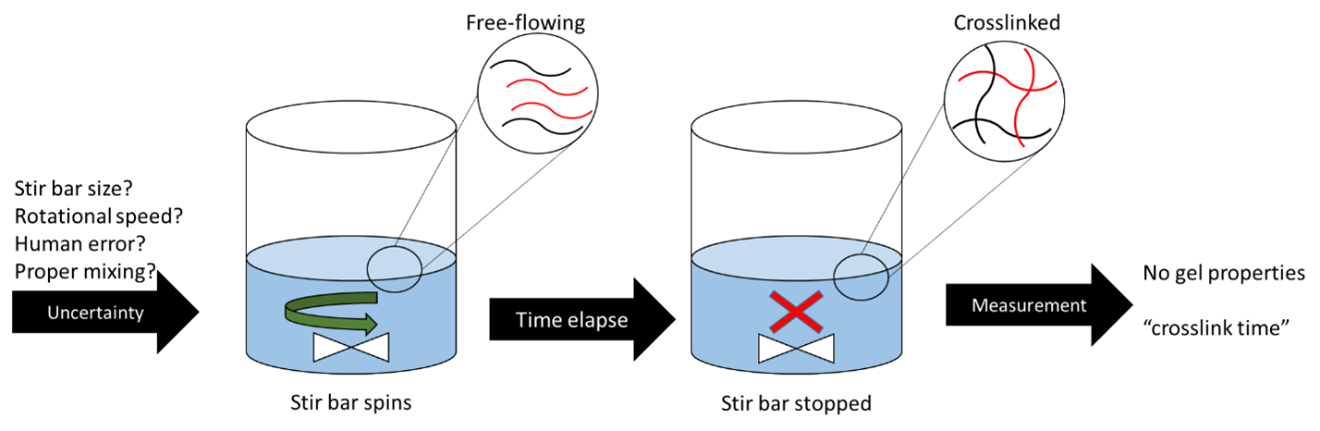

For instance, the stir bar stop method, while useful for qualitative ranking, falls short in providing precise measurements for transitions occurring in less than a second.

Stir bar stop method typically used as a qualitative metric to measure near rapid rheological transitions. Example shown for crosslinking. Time accuracy is only as good as the human pressing the start/stop button on a stopwatch.

A Novel Approach: Custom Vane and Baffled Cup Geometry

To address these challenges, an innovative method was developed using a custom-designed vane and baffled cup geometry. This approach offers several advantages:

- Reduced sample volume: Only 6 mL required, compared to ~20 mL for standard vane accessories

- Rapid mixing capability: High-speed rotation ensures near-instantaneous mixing

- Precise measurement: Captures transitions within seconds of stimulus application

Experimental Setup and Calibration

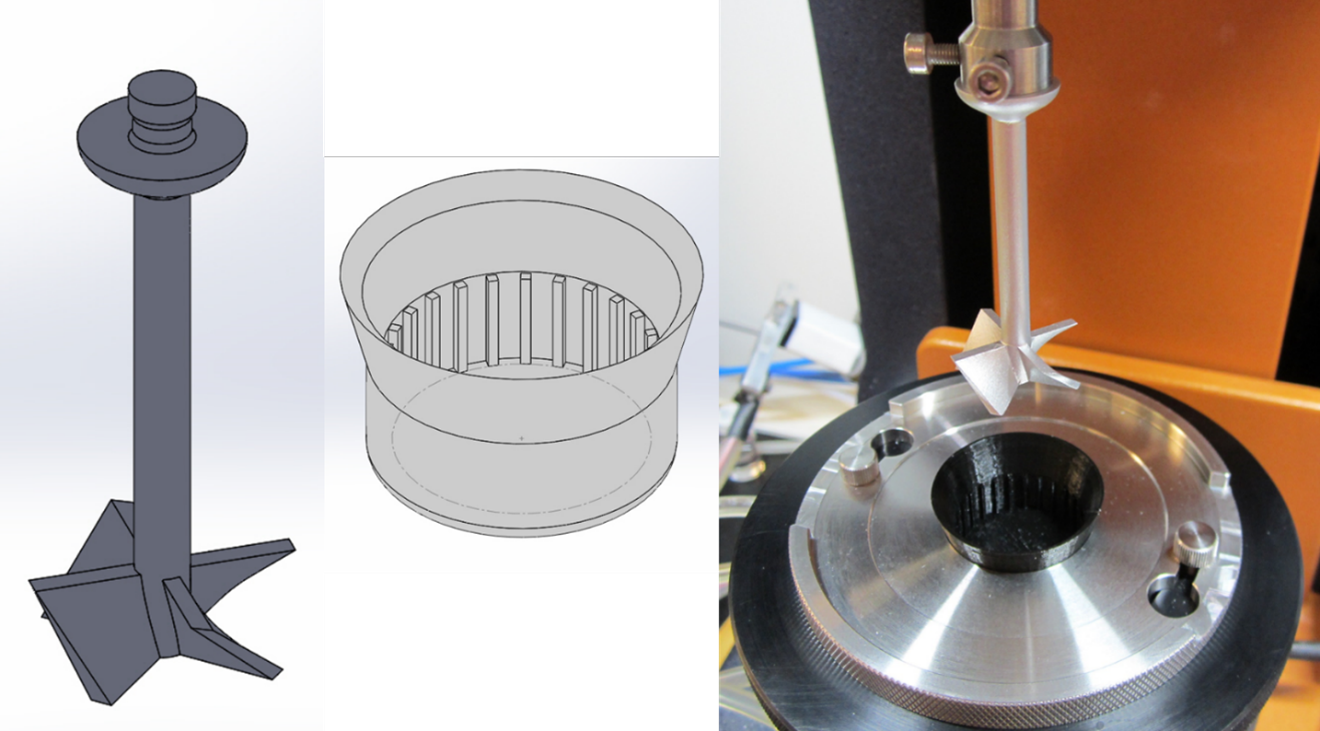

CAD sketch of custom vane (left) and custom baffled cup (middle). Machined vane and 3D printed baffled cup assembly (right).

The custom setup consists of:

- A TA Instruments DHR-2 rheometer

- A 3D-printed baffled cup

- A CNC-machined aluminum vane fixture

Due to the smaller-than-recommended gap, the geometry required calibration using both concentric cylinder and parallel plate analogies to determine accurate stress and strain factors.

Measuring Rapid Absorption Kinetics

The method was applied to measure the absorption kinetics of a powder absorbent in a liquid "spill":

- The vane rotates rapidly in the liquid

- Powder absorbent is added to the cup

- Torque is monitored until a threshold is reached

- The test switches to oscillatory mode to measure slurry modulus

Results and Implications

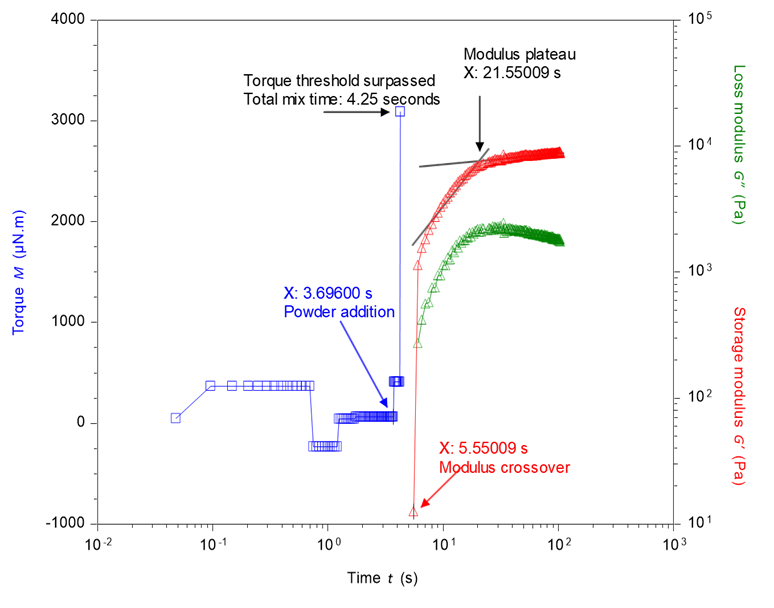

Powder absorbent added to liquid “spill.” Blue curve from the initial mix step: powder added at ~3.7 seconds, mixed rapidly for ~0.5 seconds until a predetermined torque threshold was surpassed indicating the slurry was sufficiently mixed. Red (G’) and green (G”) curves: modulus growth kinetics shows crossover within ~1.8 seconds after addition of powder and full absorbency within 17.9 seconds from addition of powder.

The custom method yielded impressive results:

- Crossover time: 1.79 seconds after powder addition

- Full absorbency: Achieved within 17.85 seconds

These precise measurements provide valuable insights into the rapid rheological changes occurring in the absorbent material system.

Conclusion

This novel approach to quantifying rapid rheological changes offers a powerful tool for material scientists and product designers. By overcoming the limitations of conventional methods, it enables more accurate and detailed analysis of fast-acting materials, potentially leading to improved designs in various applications, from spill cleanup to medical treatments. The ability to capture such rapid transitions with minimal sample volumes opens new possibilities for research and development in fields where material behavior in the first few seconds is critical. As we continue to push the boundaries of material science, tools like this will play an increasingly important role in understanding and optimizing rapid rheological phenomena.

Read the full application note.