Polymer deformulation typically involves multiple tests to identify the type of polymer, assess the presence of potential blended polymers, and evaluate the incorporation of additives such as colorants, stabilizers, and processing aids. An elegant and more rapid alternative involves a form of pyrolysis gas chromatography mass spectrometry.

During pyrolysis, polymeric materials are rapidly heated to above their thermal decomposition temperatures such that covalent bonds are broken and rearranged. The resultant smaller fragments (pyrolyzates) are then separated using gas chromatography-mass spectrometry (GC-MS). Through identification of the pyrolyzates, the original polymer can be identified.

Challenges in Polymer Identification

Often, the pyrogram of a pyrolyzed polymeric material will contain peaks that do not originate from the polymer itself but instead can be traced back to:

- Volatile or semi-volatile residual solvents

- Monomers

- Contaminants

- Additives

These additional peaks can make accurate identification of the base resin more challenging and, likewise, identification of these peaks can be complicated by interference from the pyrolyzates. Although these compounds can be removed by an extraction process prior to pyrolysis GC-MS to separately characterize the volatile/semi-volatile compounds and identify the polymer, this approach can be unnecessarily burdensome.

Multi-Step Pyrolysis GC-MS

As an alternative approach towards characterization of both additives and the base resin, polymers can be subjected to multi-step pyrolysis GC-MS. Materials are initially heated to a temperature below the thermal decomposition temperature that allows for volatile and semi-volatile compounds to be thermally desorbed prior to pyrolysis. These compounds can then be identified and evaluated separately from the pyrolyzates of the base resin. The identity of the base resin can then be determined by heating the same sample to a temperature above the decomposition temperature. In sum, multi-step pyrolysis GC-MS can be used to evaluate the additive package and base resin of a polymeric material with only a small sample and no preparation beyond transferring the material to a quartz pyrolysis tube.

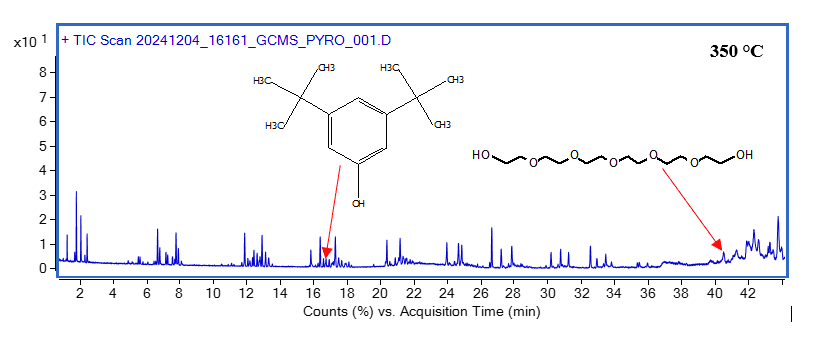

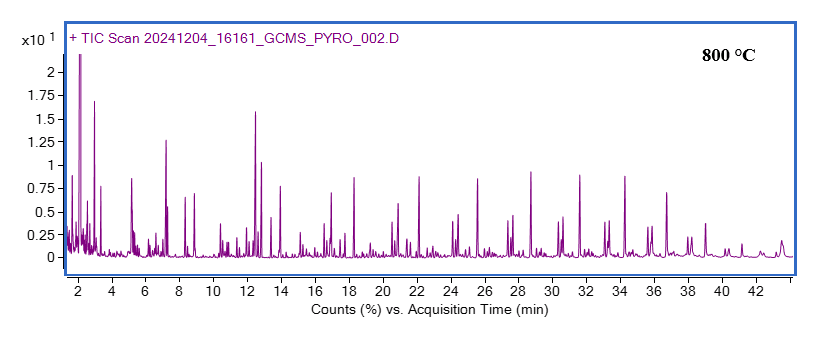

As an example of the utility of multi-step pyrolysis GC-MS, polypropylene often contains antistatic agents, slip agents, sterically hindered phenol antioxidants, and UV-absorbers. These compounds could potentially be obscured by the pyrogram that is typically associated with polypropylene pyrolysis. However, by using the multi-step approach, many of the contaminants, antioxidants, and UV-absorbers can be identified prior to pyrolysis. As shown below, thermal desorption of polypropylene at 350 °C yielded a sterically hindered phenol antioxidant, as well as a hexaethylene glycol, which likely is a functional group of a higher molecular weight slip additive. Pyrolysis of the same sample at 800 °C yielded a pattern of 1-alkenes consistent with polypropylene.