New Ethylene Oxide Sterilization Standards Proposed

The Environmental Protection Agency (EPA) is proposing new standards on chemicals used to sterilize medical devices, including ethylene oxide (EO/EtO), one of the more commonly used sterilants. However, ethylene oxide has recently been scrutinized due to safety concerns about workers' EtO exposure at sterilization facilities.

The EPA is proposing a decrease in the highest allowable airborne concentration of ethylene oxide. The proposed level of EtO is 0.2 parts per million (ppm), which is lower than the current standard of 1 ppm.

This proposed standard is based on recent research that suggests that long-term exposure to an amount of EtO greater than 0.2 ppm can be hazardous to human health. The EPA also proposes that sterilization facilities must implement rigorous monitoring and reporting protocols to ensure the safety of workers and surrounding communities.

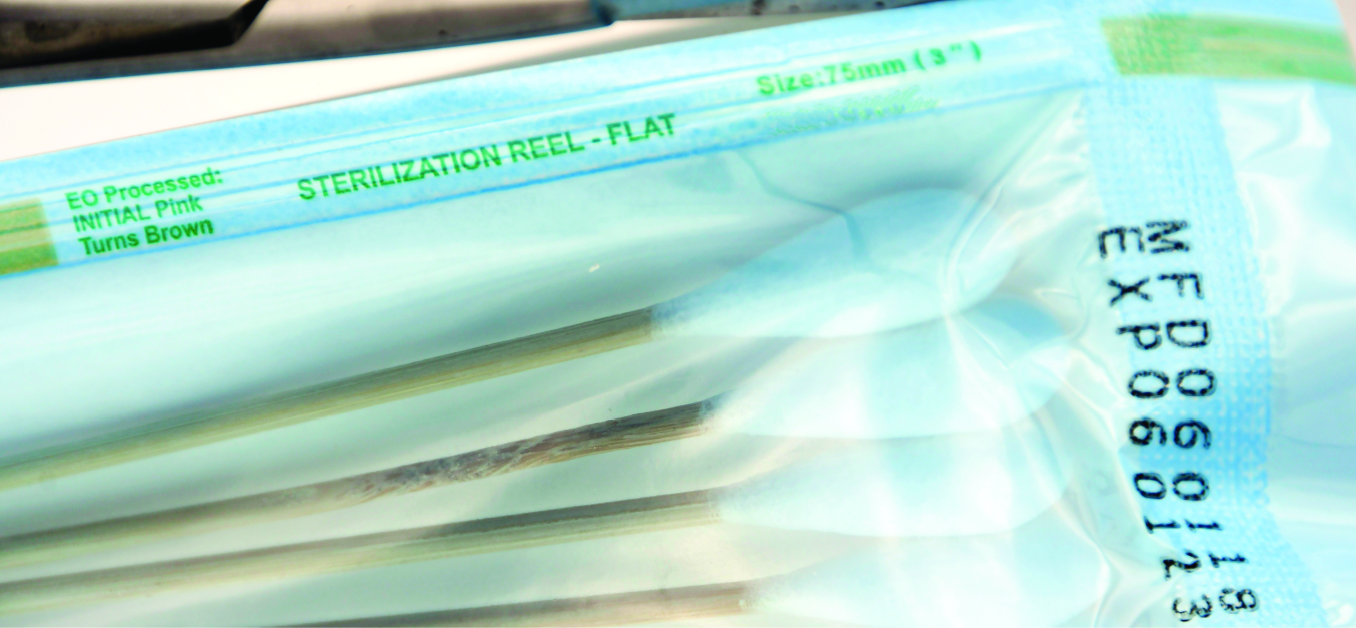

Although ethylene oxide is a toxic gas, it is an effective sterilant for many medical devices that cannot be sterilized by ionizing radiation (gamma, e-beam, or X-ray) or through steam autoclaves, due to the polymer composition of these devices.

Some trade associations are concerned about the EPA's proposal. They believe the safety requirements will take longer than 18 months to put into place. A slowdown of EtO sterilization could affect the supply chain of billions of medical devices per year, negatively impacting patients' access to health care.

Consider Alternative Sterilization Modalities

This slowdown may push device manufacturers to consider other sterilization modalities. CPG has expertise in radiation chemistry of polymers, as well as how temperature can affect these materials, and can assist clients in developing and validating appropriate sterilization processes for medical devices.

Medical device manufacturers who make changes in their sterilization method, process or facility outlined in their original Premarket Approval must submit a PMA supplement so that the FDA can review the changes. 510(k) holders would need to consult FDA guidance on whether a change in sterilization modality on their device would require a new 510(k) submission.

CPG's team of materials experts can explain the complexities of the sterilization process and provide guidance on the best options to meet regulatory requirements. We can help clients evaluate sterilization modalities, and if a change in the sterilization method is required, we can provide support in filing the appropriate PMA supplement or 510(k).

Our polymer scientists can provide answers to any questions you may have and offer a comprehensive plan to ensure your medical device is compliant with FDA requirements. Contact one of our scientists today for a consultation.