The California Phthalate Ban: A New Era for Medical Devices

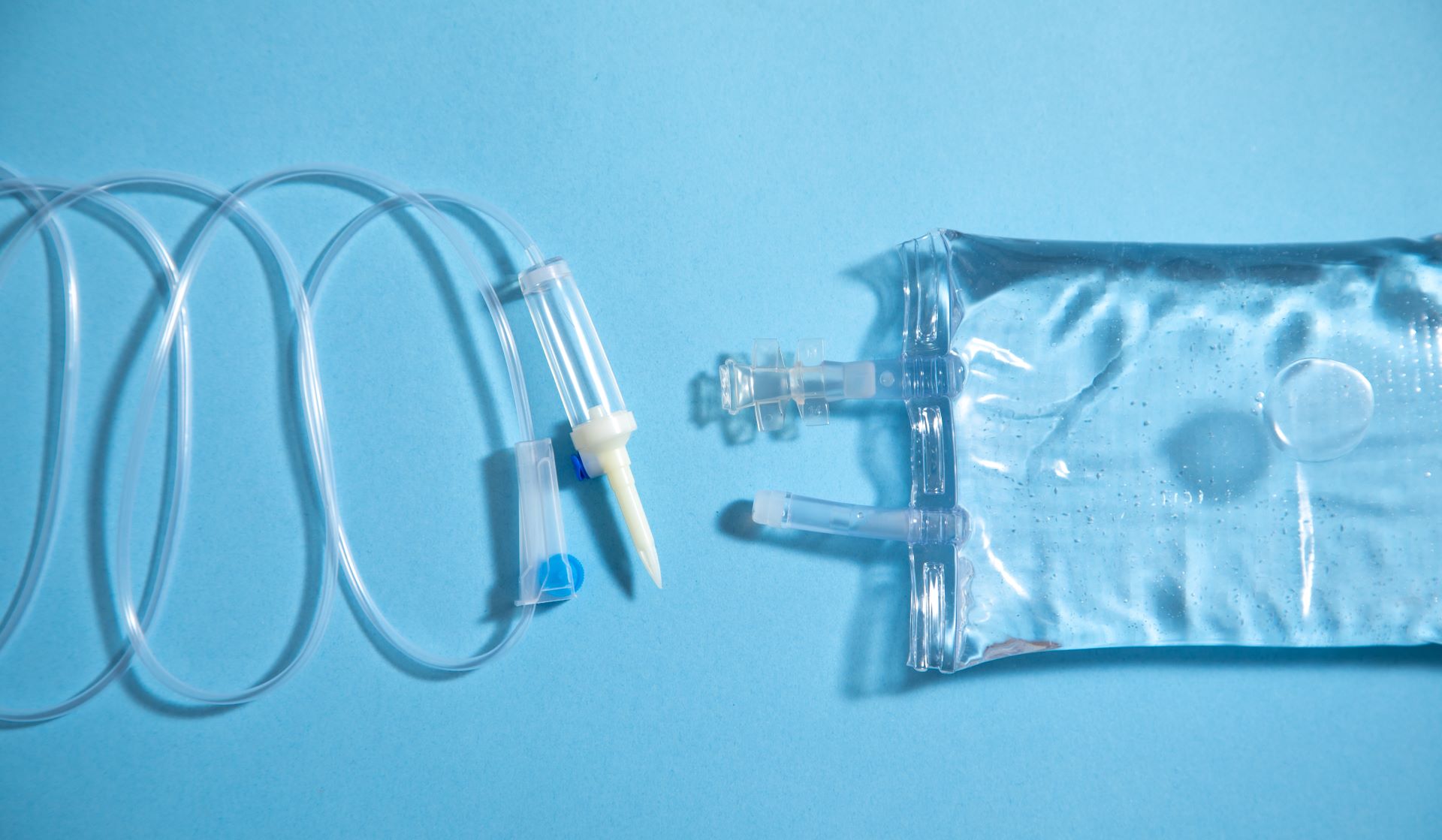

California, known for its progressive stance on environmental and health issues, is once again at the forefront of regulatory change. On September 25, 2024, California Governor Gavin Newsom signed the Toxic-Free Medical Devices Act (AB 2300) into law. The legislation prohibits the use of certain ortho-phthalates, specifically di-(2-ethylhexyl) phthalate (DEHP), in intravenous (IV) solution containers and tubing products.

What Are Phthalates?

Phthalates are a group of chemicals used to make plastics, primarily polyvinyl chloride (PVC),more flexible and durable. These additives are commonly found in various medical products, including medical devices such as IV bags, tubing, and catheters. They have also been used more broadly in industries ranging from toys to tools, although legislation is generally already in place outside of medical devices. In some cases, these compounds can be present at greater than 30% of the mass of the material.

Toxic Free Medical Devices Act – California AB 2300

California's ban on phthalates in medical devices stems from growing concerns about their potential health risks. Phthalates are known endocrine disruptors and have been linked to various health issues, including reproductive problems and developmental disorders.

The ban on intentionally added DEHP will take effect on January 1, 2030, for IV containers, and January 1, 2035, for IV tubing. This legislation aligns with similar restrictions in the European Union. It is important to note that unintentionally added DEHP may still be present in quantities at or below 0.1% weight per weight (w/w).

The legislation exempts certain medical devices, including:

-

Human blood collection and storage bags

-

Apheresis and cell therapy blood kits and bags, including integral tubing

DEHP’s unique properties are considered necessary for improved red blood cell quality and stability. In the case of blood storage, changing materials is not so straightforward because DEHP acts to stabilize the blood and improve the quality of the stored blood, a phenomenon that is still not well understood.

Implications for the Medical Device Industry

Regulatory Compliance

The California medical device phthalate ban will require some manufacturers to reformulate their products, potentially leading to significant changes in production processes and materials used, including:

-

Reviewing and updating product portfolios to identify all items containing DEHP

-

Developing and implementing plans to phase out DEHP-containing products

-

Ensuring compliance with new regulations across the supply chain

-

Updating documentation and labeling to reflect changes in material composition

Supply Chain Adjustments

The new legislation will necessitate changes throughout the supply chain, including:

-

Sourcing new raw materials and components

-

Qualifying new suppliers who can provide phthalate-free alternatives

-

Potentially relocating or modifying manufacturing facilities

-

Updating inventory management systems to track and phase out DEHP-containing products

Innovation and R&D

Manufacturers will need to innovate and develop alternative materials that can provide the same functionality as phthalates without the associated health risks. This involves:

-

Investing in research and development of new plasticizers and materials

-

Collaborating with material scientists and chemical engineers to find suitable alternatives

-

Conducting extensive testing to ensure new materials meet performance and safety standards

-

Potentially redesigning products to accommodate new materials

Testing and Screening

Companies will need to implement rigorous testing protocols to ensure their products are phthalate-free:

-

Developing and validating new analytical methods for detecting phthalates

-

Implementing more stringent quality control measures throughout the manufacturing process

-

Conducting regular audits and testing of raw materials and finished products

-

Training staff on new testing procedures and regulatory requirements

Global Impact and Market Dynamics

While specific to California, it is part of a growing trend to phase out phthalates in medical devices. Although currently the FDA does not prohibit the use of these compounds in medical devices, the California legislation increases pressures on US manufacturers to phase out these materials, and increasingly aligns with EU proposals. This may result in:

-

Pressure on manufacturers to adopt phthalate-free alternatives globally

-

Changes in competitive landscape as companies adapt at different rates

-

Potential for early adopters to gain market share in regions with stricter regulations

-

Increased scrutiny of phthalates in medical devices by regulatory bodies worldwide

Challenges and Opportunities

The ban presents both challenges and opportunities for the medical device industry. Initially, there may be increased costs associated with research, development, and retooling of production lines. However, this could lead to more sustainable and safer products in the long run.

By eliminating potentially harmful chemicals from medical devices, manufacturers can boost consumer confidence and potentially gain a competitive edge in the market. Medical device manufacturers should start exploring alternative materials and testing methodologies to ensure compliance with new regulations.

The California ban on phthalates in medical devices represents a significant step towards safer healthcare products. As the regulatory landscape continues to evolve, adaptability and a commitment to safety will be key for success in the medical device industry.

How Cambridge Polymer Group Can Help

As experts in polymer science and material selection, Cambridge Polymer Group is well-positioned to assist companies in navigating these changes.

Material Selection

In addition to regulatory considerations, the choice of starting material must be driven by the anticipated end-use. Our team provides holistic thinking on material selection, considering factors such as downstream sterilization techniques that often dictate upstream material choices. We begin by obtaining a detailed description of your target application, including the expected environment, intended lifespan, and any specific material properties required.

We can help you evaluate potential alternatives that satisfy both California and EU requirements. Our approach considers not only the engineering and performance aspects but also biological safety and material regulatory trends. We assemble a list of candidate materials, filter them based on your specific needs, and can perform custom tests relevant to your application.

Chemical Characterization

Our state-of-the-art instrumentation and experienced scientists can perform extractables and leachables studies, identify and quantify chemical constituents, and evaluate potential degradation products. We use techniques such as Q-TOF, GC-MS, LC-MS, FTIR, and NMR to provide detailed chemical profiles of materials. Our testing protocols are designed to meet regulatory requirements and industry standards, ensuring thorough characterization of your device materials.

Toxicological Risk Assessment

To provide comprehensive support to our clients, Cambridge Polymer Group has partnered with Gradient, a leading environmental and risk sciences consulting firm. This collaboration allows us to offer expert toxicological risk assessment services for medical devices. Gradient's board-certified toxicologists (DABTs) bring decades of in-house experience at medical device companies. They have a strong track record in helping clients achieve regulatory approval and address inquiries from US FDA and European Union (EU) notified bodies.

Biological Evaluation Plan

Our team at Cambridge Polymer Group can conduct biological risk assessments for medical devices in accordance with ISO 10993 standards. We evaluate the biocompatibility of materials, assess potential biological hazards, and determine the overall biological safety of devices. Our approach includes analyzing chemical characterization data, reviewing toxicological information, and assessing the risk of adverse biological responses. We can help you develop a biological evaluation plan, interpret test results, and prepare comprehensive biological risk assessment reports to support regulatory submissions.

As the medical device industry adapts to these new regulations, Cambridge Polymer Group and Gradient are committed to providing the expertise and support needed to ensure compliance and maintain product quality. For more information or to discuss how we can assist your company, please contact us.